1390 Masini fa'aoti sa'o maualuga

Fa'aaliga Oloa

Parakalafa fa'apitoa

| Nofoaga faigaluega | 1300*900mm | Fa'ailoga Ulu Laser | Raytools |

| Mana leisa fiber | Filifiliga: 1000W/1500w/2000w/3000W ma isi. | Vaega Autu | afi afi |

| Max tipi saoasaoa | 0-40m/min | Vaega:

| Fa'apipi'i atoatoa |

| Toe fai le tulaga sa'o | 0.02mm | Auala ole Faagaioiga | galu faifai pea |

| paoa sapalai | 220v/50Hz/60Hz | afi ma aveta'avale | Iapani YASKAWA servo afi & aveta'avale/Farani fa'aitiitia |

| vevela o le siosiomaga | 0-35°C | Lagolagoina Fa'asologa o Ata | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Taimi faigaluega faifaipea | 24 itula | Vaega tipi | 1300*900mm,1300*1300mm |

| O le mamafa o le masini | 1500kg | Fa'atauga Autu | Maualuga-saʻo |

| Ola faanatura o le laser | 100000itula | Faiga fa'asalalau | Fa'aliliuina o polo sikuli |

| Polokalama Pulea | Cypcut | MAX fa'avave | 0.5G |

| Faiga malulu | Suavai malulu | Toe fai le sa'o o le nofoaga:

| ±0.006mm |

Otioti mafiafia

| Laisa tipi tipi | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Mea | mafiafia | saoasaoa m/min | saoasaoa m/min | saoasaoa m/min | saoasaoa m/min | saoasaoa m/min | saoasaoa m/min | saoasaoa m/min |

| Uamea kaponi | 1 | 8--13 | 15--24 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 3.0--4.5 | 5--7.5 | 5.5--8 | 7--9 | 8--10 | 9--12 | 10--13 | |

| 3 | 1.8--3.0 | 2.4--4 | 3.5-4.8 | 4--6.5 | 4.5--6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5--4.5 | 4.0--5.0 | 4.2--5.5 | 4.7--5.5 | |

| 5 | 0.9--1.1 | 1.8--2 | 2.5--3 | 3--3.5 | 3.0--4.2 | 3.5--4.2 | 3.8--4.5 | |

| 6 | 0.6--0.9 | 1.4--1.6 | 1.8--2.6 | 2.5--3.2 | 3.0--3.5 | 3.0--4 | 3.3--4.2 | |

| 8 |

| 0.8--1.2 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | 2.5--3.5 | |

| 10 |

| 0.6--1.0 | 1.1-1.3 | 1.4--2.0 | 1.5--2.5 | 1.8--2.5 | 2.2--2.7 | |

| 12 |

| 0.5--0.8 | 0.9--1.2 | 1.2--1.6 | 1.4--2 | 1.6--2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9--1.4 | 1.0--1.6 | 1.5--1.8 | 1.7--1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8--1.2 | 0.8--1.2 | 0.8--1.5 | 0.9--1.7 | |

| 18 |

|

| 0.4--0.6 | 0.7--1 | 0.8--1.1 | 0.9--1.2 | 0.9--1.2 | |

| 20 |

|

|

| 0.6--0.8 | 0.7--1 | 0.8--1.1 | 1.0--1.5 | |

| 22 |

|

|

| 0.4--0.6 | 0.6--0.8 | 0.7--0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3--0.5 | 0.4--0.6 | 0.5--0.7 | |

| Apa siliva | 1 | 8--13 | 18--25 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 2.4--5.0 | 7--12 | 10--17 | 18--21 | 20--30 | 30--42 | 40--55 | |

| 3 | 0.6--0.8 | 1.8--2.5 | 4--6.5 | 8--12 | 12--18 | 18--24 | 30--38 | |

| 4 |

| 1.2--1.3 | 3--4.5 | 6--9 | 8--12 | 10--18 | 18--24 | |

| 5 |

| 0.6--0.7 | 1.8-2.5 | 3.0--5.0 | 4--6.5 | 8--12 | 12--17 | |

| 6 |

|

| 1.2-2.0 | 3.0--4.3 | 4.0--6.5 | 6--9 | 8--14 | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8--3.0 | 4--5 | 6--8 | |

| 10 |

|

|

| 0.8--1 | 0.8--1.5 | 1.8--2.5 | 3--5 | |

| 12 |

|

|

| 0.5--0.8 | 0.6--1.0 | 1.2--1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5--0.8 | 0.6--0.8 | 1.2--1.8 | |

| 20 |

|

|

|

| 0.4--0.5 | 0.5--0.8 | 0.6--0.7 | |

| 25 |

|

|

|

|

| 0.4--0.5 | 0.5--0.6 | |

| 30 |

|

|

|

|

|

| 0.4--0.5 | |

| Alumini | 1 | 4--5.5 | 6--10 | 20--25 | 25--40 | 40--55 | 55--65 | 80--90 |

| 2 | 0.7--1.5 | 2.8--3.6 | 7--10 | 10--18 | 15--25 | 25--35 | 35--50 | |

| 3 |

| 0.7--1.5 | 4--6 | 7--10 | 10--15 | 13--18 | 21--30 | |

| 4 |

|

| 2--3 | 4--5.5 | 8--10 | 10--12 | 13--18 | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | 6--10 | 9--12 | |

| 6 |

|

| 0.7--1 | 1.5--2.5 | 3.5--4 | 4--6 | 4.5--8 | |

| 8 |

|

|

| 0.7--1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5--0.7 | 1--1.5 | 1.5--2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7--0.9 | 0.8--1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5--0.7 | 0.7--1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5--0.7 | 0.7--1 | |

| 25 |

|

|

|

|

|

| 0.5--0.7 | |

| 'apamemea | 1 | 4--5.5 | 6--10 | 14--16 | 25--35 | 35--45 | 50--60 | 70--85 |

| 2 | 0.5--1.0 | 2.8--3.6 | 4.5--6.5 | 10--15 | 10--15 | 25--30 | 30--40 | |

| 3 |

| 0.5--1.0 | 2.5--3.5 | 5--8 | 7--10 | 12--18 | 15--24 | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | 8--10 | 9--15 | |

| 5 |

|

| 1.4-1.6 | 2.5--3.2 | 3.5-5.0 | 6--7 | 7--9 | |

| 6 |

|

|

| 1.2--2.0 | 1.5--2.5 | 3.5--4.5 | 4.5--6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8--1.5 | 1.6--2.2 | 2.4--4 | |

| 10 |

|

|

|

| 0.5--0.8 | 0.8--1.4 | 1.5--2.2 | |

| 12 |

|

|

|

|

| 0.6--0.8 | 0.8--1.5 | |

| 16 |

|

|

|

|

|

| 0.6--0.8 | |

Vaega Autu

Fa'aaogāga

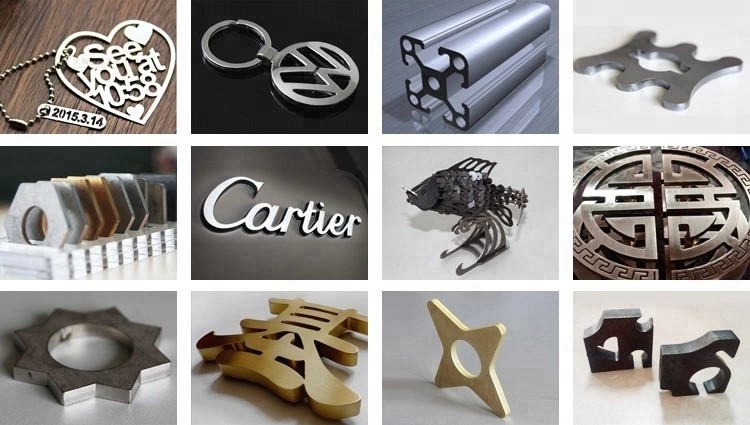

Alamanuia fa'aoga:

1390 High Precision laser Cutting Machine o loʻo faʻaaogaina lautele i le gaosiga o Billboard, Faʻasalalauga, Faʻailoga, Faʻailoga, Mataitusi uʻamea, Mataʻitusi LED, Mea Tau umukuka, Tusi Faʻasalalauga, Faʻasalalauga Faʻasalalau Faʻasalalau, Mea Faʻapipiʻi ma Vaega, Umea, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Vaega, Mea Faʻatekonolosi, Mea Faʻatekonolosi, Mea Faʻaigoa Taʻavale. e mafai ona faagaoioia o mafai i le faagasologa o le tipiina leisa.

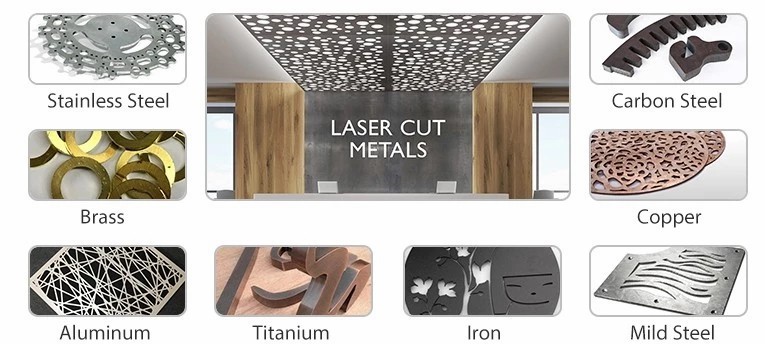

Mea Fa'aaogā:

Pepa u'amea u'amea, ipu uamea malu, pepa uamea kapo, pa'u u'amea aloi, pa'u u'amea puna, ipu u'amea, u'amea u'amea, pepa u'amea, pa'u alumini, pa'u kopa, laupepa apamemea, ipu apamemea, ipu auro, ipu siliva, ipu titanium, pepa u'amea, ipu uamea, paipa ma paipa, ma isi.

Fa'ata'ita'iga

Fa'amanuiaga

1.Cutting lelei, e oo atu i le 0.05-0.1mm. Fa'aoga le kesi fesoasoani talafeagai, fa'amama ma lamolemole le fa'alava, e le mana'omia le fa'alelei lona lua.

2.Focusing le ulu tipi automatic.using of faaulufale mai maualuga-agai i luma capacitive sensor, taimi atoa dynamic plate height.Adjusting le maualuga tipi otometi e taofia ai le fetoaiga, e mafai ona e tipiina le ipu le tutusa.

3. Fa'aaogaina masini tipi fa'aulufale mai servo afi ta'avale, fa'aulufale mai maualuga-sa'o laina laina, vave, maualuga sa'o e o'o atu i le 0.01mm. Le soifua tautua umi.

4.O le faʻaogaina o le fiber lasers maualuga, o masini autu e faʻaulufale mai. Maualuluga maualuga, ola umi, leai ni sapalai, leai se tausiga.

5. Faʻataʻitaʻiga faʻapitoa o le toe faʻaleleia o le paʻu auro, pefu ma le pefu na aoina uma le masini toe faʻaleleia. Ia o le leiloa i se tulaga maualalo.

6.Mo auro ma siliva teuga alamanuia faapolofesa faiga tipi tipitipi leisa, faatasi ai ma le auala optimization, tipi amata tulaga optimization, multi-layer, galuega faatulagaina, faasaoina le taimi ma mea.

7. Laʻititi laʻititi, maualalo le faʻaaogaina o le malosi, faʻaitiitia sapalai, tausiga faigofie. Faatasi ai ma le ea compressed e mafai foi ona tipi, tau maualalo.